Clay cutters

-

What are the best setting and how to work with them to make cutters for charms.

-

@Koralys-Torres said in Clay cutters:

What are the best setting and how to work with them to make cutters for charms.

- Modeling settings

Wall thickness: 0.8 to 1.2 mm for small charm cutters.

Cutter edge: Slight outward taper helps release clay. A 0.3 to 0.5 mm thin cutting edge works well.

Height: 10 to 15 mm so you can hold it comfortably.

Bottom lip: Add a 0.4 to 0.6 mm blunt edge for stability.

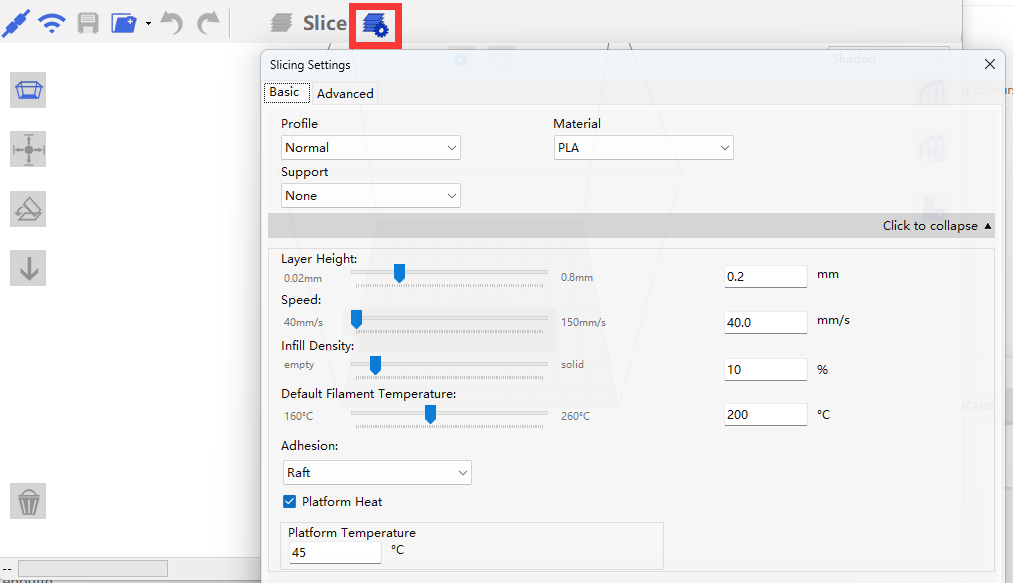

- Slicer settings

Layer height: 0.12 to 0.20 mm for a smooth edge.

Walls/perimeters: 3 to 4 walls for strength.

Infill: 20 to 30 percent is enough.

Top layers: 3 to 5.

Material: PLA works fine. PETG if you need more durability.

Nozzle: Standard 0.4 mm.